Disintegrator/ Dissolvers

Disintegrator/ Dissolvers

If you thought it couldn't be done, think again. Silverson's mighty Disintegrator 2500 mixing system will disintegrate, solubilize or disperse the largest of solids - up to 40" across - in a single operation, and in times you wouldn't believe.

The Disintegrator 2500 incorporates a powerful and unique Silverson mixer located in the bottom of a custom-built vessel. The mixer exerts a massive suction downwards from the surface of the liquid, pulling down even the most buoyant of solids, no matter what the size. These solids are literally ripped apart and dispersed throughout the mix, and with the refinement of a Silverson In-Line mixer included in the system, are totally solubilized or suspended.

For smaller solids, Silverson offers the Duplex Disintegrator/ Dissolver, which was specifically developed for the disintegration and solubilization of solid rubbers and polymers for the lube oil and adhesive industries.

How It Works

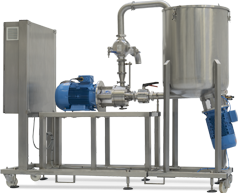

The Disintegrator 2500 is a self-contained unit of high power comprising a specially designed Silverson high shear rotor/stator disintegrating workhead set into a custom-built dedicated vessel coupled with a Silverson high shear In-Line mixer.

The unit is charged with liquid and started. Large solids are fed into the vessel and drawn down to the workhead which will rapidly shear lumps and slices off the edges and corners. These will be drawn into the interior of the workhead, driven by centrifugal force to the periphery and further sheared by the rotor tips against the edges of the stator perforations as they are expelled radially from the head.

Rapid fragmentation of the large solids continues until all the particles are small enough to be drawn into the workhead for further disintegration. Materials are discharged horizontally from the workhead and forced up the vessel walls. This cycle continues until all solids are reduced to granular size.

Once the solids are reduced to granular size the self-pumping In-Line mixer is started. The product is drawn from the bottom of the vessel, processed through the In-Line mixer’s high shear rotor/stator workhead and passed back into the top of the vessel ensuring complete solution or suspension.

-

Stage 1

Stage 1

The unit is charged with liquid and started. Large solids are fed into the vessel and drawn down to the workhead which will rapidly shear lumps and slices off the edges and corners. These will be drawn into the interior of the workhead, driven by centrifugal force to the periphery and further sheared by the rotor tips against the edges of the stator perforations as they are expelled radially from the head.

-

Stage 2

Stage 2

Rapid fragmentation of the large solids continues until all the particles are small enough to be drawn into the workhead for further disintegration. Materials are discharged horizontally from the workhead and forced up the vessel walls. This cycle continues until all solids are reduced to granular size.

-

Stage 3

Stage 3

Once the solids are reduced to granular size the self-pumping In-Line mixer is started. The product is drawn from the bottom of the vessel, processed through the In-Line mixer’s high shear rotor/stator workhead and passed back into the top of the vessel ensuring complete solution or suspension.

Videos

D-2500 – Disintegrator/Dissolver

D-2500 – How It Works

Mixer Options

Technical Information

- Capacity

- 250 to 25,000 gallons

- Components

- Silverson Disintegrator 2500 systems typically include:

- Silverson Bottom Entry Disintegrator/Dissolver – provides rapid disintegration of solids and wetting of powders and is the prime mover of the fluid in the vessel.

- Silverson In-Line High Shear Mixer – maximizes the solution of the fine particles created by the Bottom Entry unit and allows for instant homogenization of additive fluids.

- Special Disintegrator 2500 vessel, associated piping, valves, fittings and controls – optimizes mixing characteristics to suit application needs.

- Typical Applications

- Rapid solution of rubber and polymer blocks into lubricating oils, solvents, and asphalt for the production of VM lube oils, adhesives, and polymer-modified asphalts for road surfacing.

- Recovery of waste candy.

- Wet crumbing of waste rubber.

- Rapid dispersion of large volumes of powder or materials which are difficult to wet out and have a tendency to “raft.”

- Dispersion of filter cakes.