Boutique cosmetic company Donna-Klare’s approach to skincare is a paradigm shift. Based on traditional herbalism, they use only the highest quality plant-based ingredients and formulate, trial, and develop their products in-house from start to finish all without the use of synthetic stabilizers, ingredients, colors or fragrances.

The proof is in the mixer

Mixing is a pivotal step when making cosmetic creams and can make or break whether your product has the right consistency, skin-feel and functionality. In order to form a stable emulsion without the use of synthetic materials, using high shear mixers is essential. Donna-Klare sought out Silverson as their high shear mixing solution due to Silverson’s stellar reputation and the design and build quality of our machines. Plus our global network of representatives meant that there was local, on-site assistance available via Silverson's representatives in New Zealand: Advanced Packaging Systems. Our reps guided Donna-Klare with the selection, purchase and post-sales support which they said: “made working with Silverson a pleasure”.

One machine, a multitude of processes

With over 40 interchangeable workheads and mixing assemblies available for the Silverson laboratory mixer, this one machine can be adapted to perform a wide range of mixing operations that would otherwise warrant additional mixing equipment. Emulsifying, homogenizing, disintegrating, dissolving, dispersing, blending, particle size reduction, deagglomerating—all can be done with a single machine simply by changing from one workhead to another.

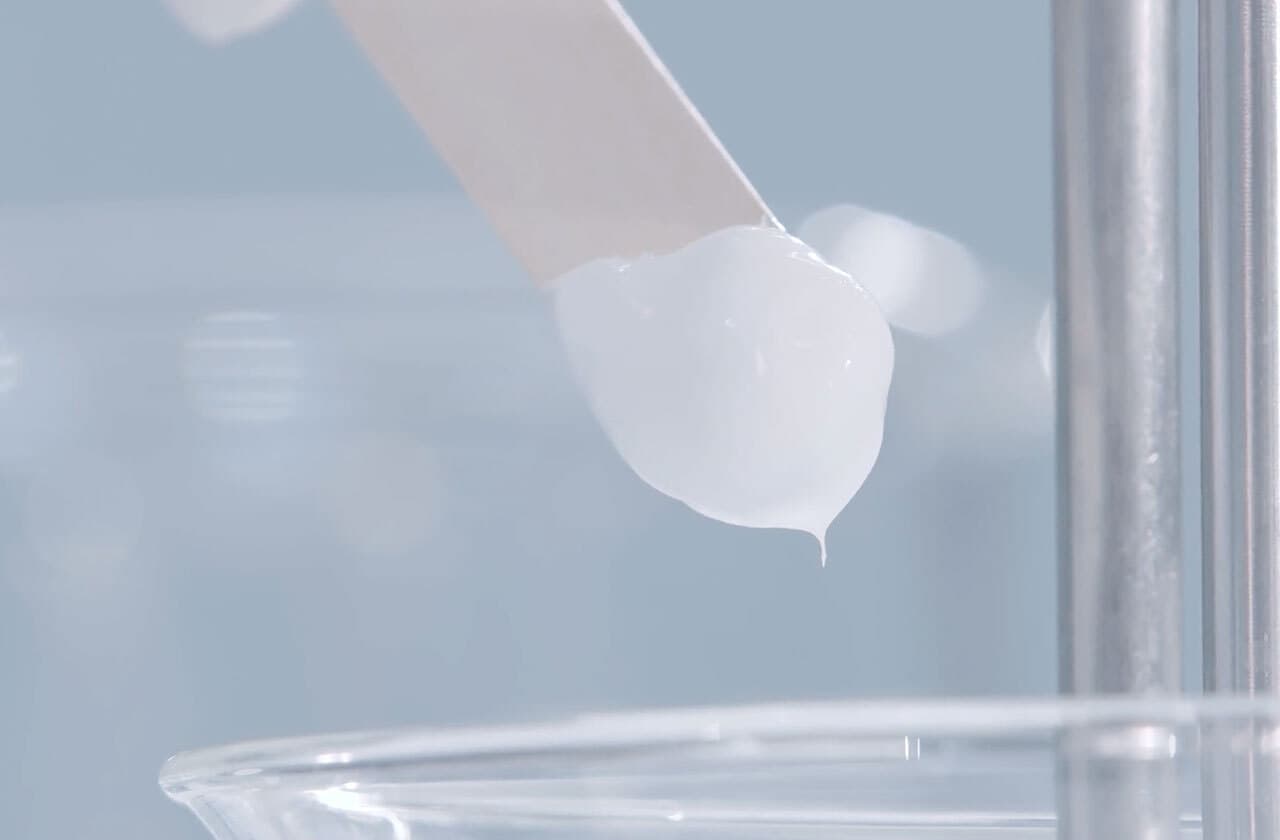

Donna-Klare found that the performance of the Silverson lab mixer with its wide range of workheads allowed them to experiment with the process and formulation until they produced their optimal end-product: a highly stable and very fine luxury cream emulsion, with cream particles under 5 microns in order to achieve deep skin penetration.

Cream of the crop

Not only has the Silverson lab mixer improved the end product effectiveness, but it has also optimized the production of the creams, virtually eliminating air and heat during the emulsifying phase. Other benefits of high shear mixing include:

- Consistent product quality and repeatability

- Agglomerate-free mix

- Stable emulsion

- Rapid mixing time

You can read more about how we troubleshoot common mixing problems during cream/lotion production in our mixing guide below.

Setting the stage for production-scale

For now, Donna-Klare is working on the laboratory scale but as the business continues to grow, they plan to use Silverson’s production-scale mixers to keep up with customer demand. All Silverson mixing equipment is engineered to the same fine tolerances, meaning Donna-Klare can easily scale-up without having to reformulate their products for manufacture on a larger scale. It’s a win-win for all.

Ready to make the crème de la crème?

Whether you need help developing the next best thing in skincare or you simply want to improve your existing cream or lotion-making process, Silverson is ready to help guide you to success.

If you’d like to find out more about Donna-Klare, please visit their website.