Soft Drink Manufacture - Preparation of Sugar Syrups

The sugar content of carbonated and still soft drinks varies considerably according to whether the product is to be supplied ready to drink, or as a concentrate (often referred to as a “syrup”). A typical formulation would also contain flavoring or concentrated fruit juice, acidity regulators, preservatives, stabilizers, antioxidants and coloring. With “Diet,” and other “sugar-free” drinks the sugar content is replaced with artificial sweeteners such as Aspartame (covered in a separate report).

The Process

One of the first stages in a typical manufacturing process is preparation of a sugar syrup. Sugar is used in either granulated or liquid form. Liquid sugar simply requires blending with water, however when granulated sugar is used, a number of processing factors must be considered:

- Small scale production of syrups with a low sugar content can be carried out at ambient temperature. However with some concentrated products, sugar solutions at 60% or above are not uncommon, requiring heating of the water to aid dissolving.

- In large scale operations, heating to around 95℉ (35℃) may be carried out to speed up dissolving.

- Other powdered ingredients may be dry premixed with part of the sugar, which helps to prevent them from agglomerating and “weights” light powders which tend to float.

The Problem

- Liquid sugar can be considerably more expensive than granulated sugar.

- Dissolving of granulated sugar by simple agitation is a slow process.

- Conventional agitators cannot dissolve high concentrations of sugar at ambient temperatures.

- Heating the water to aid solution adds to costs and is energy inefficient.

- The cooling process further adds to costs and process time.

- Crystallization of the syrup can occur during heating/cooling.

- Incomplete solubilization can lead to sedimentation or even blocking of vessel outlets.

The Solution

A Silverson High Shear Mixer can substantially reduce mixing times and eliminate the need for heating the water.

This can be achieved with in-tank Batch Mixers or by adding a Silverson In-Line Mixer to the existing process. This operates as follows:

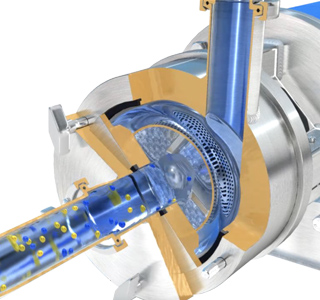

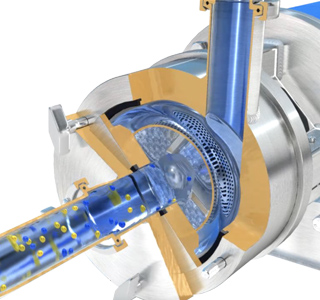

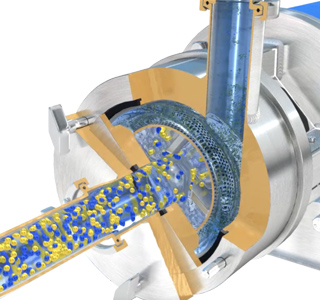

Stage 1

The high speed rotation of the rotor blades creates a powerful suction which draws the water and sugar granules from the vessel into the workhead.

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are subjected to a milling action in the gap between the rotor and the stator wall.

Stage 3

The product is forced out through the stator as fresh materials enter the workhead. In a short mixing cycle all the material passes through the workhead, progressively reducing particle size and exposing an increasing surface area of sugar to the surrounding liquid, accelerating the dissolving process.

-

Stage 1

Stage 1

The high speed rotation of the rotor blades creates a powerful suction which draws the water and sugar granules from the vessel into the workhead.

-

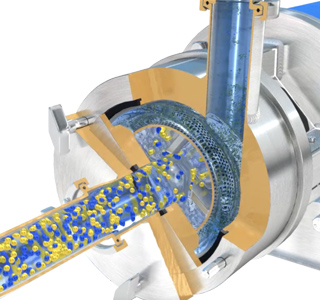

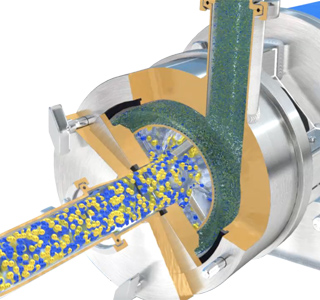

Stage 2

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are subjected to a milling action in the gap between the rotor and the stator wall.

-

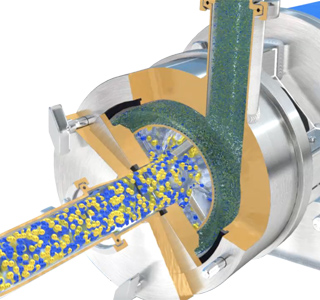

Stage 3

Stage 3

The product is forced out through the stator as fresh materials enter the workhead. In a short mixing cycle all the material passes through the workhead, progressively reducing particle size and exposing an increasing surface area of sugar to the surrounding liquid, accelerating the dissolving process.

The Advantages

- The combination of granule size reduction and vigorous mixing dramatically reduces mixing times.

- A 66% sugar syrup can be produced at ambient temperature. Click here to see the video.

- Increased versatility allows the manufacturer to use sugar in granulated or syrup form.

- A Silverson mixer can also disperse and hydrate thickening and stabilizing agents such as CMCs and Xanthan gum in a fraction of the time taken by other means.

There are several products in the Silverson range suitable for this application, the selection of which is dictated by individual process requirements including batch size.

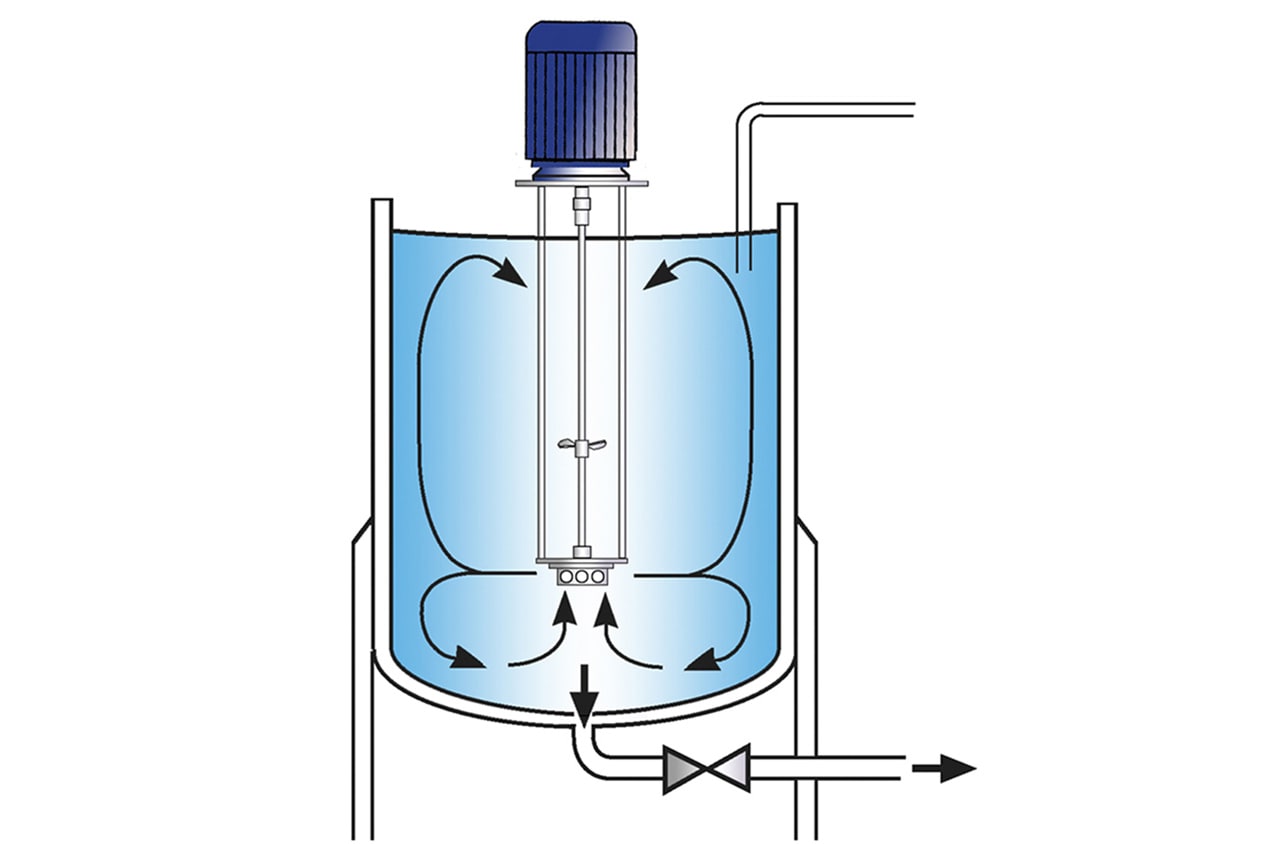

High Shear Batch Mixers

- Suitable for batch sizes up to 500 US gallons

- Many units can be used on mobile floor stands

- Small units available for R&D and pilot production

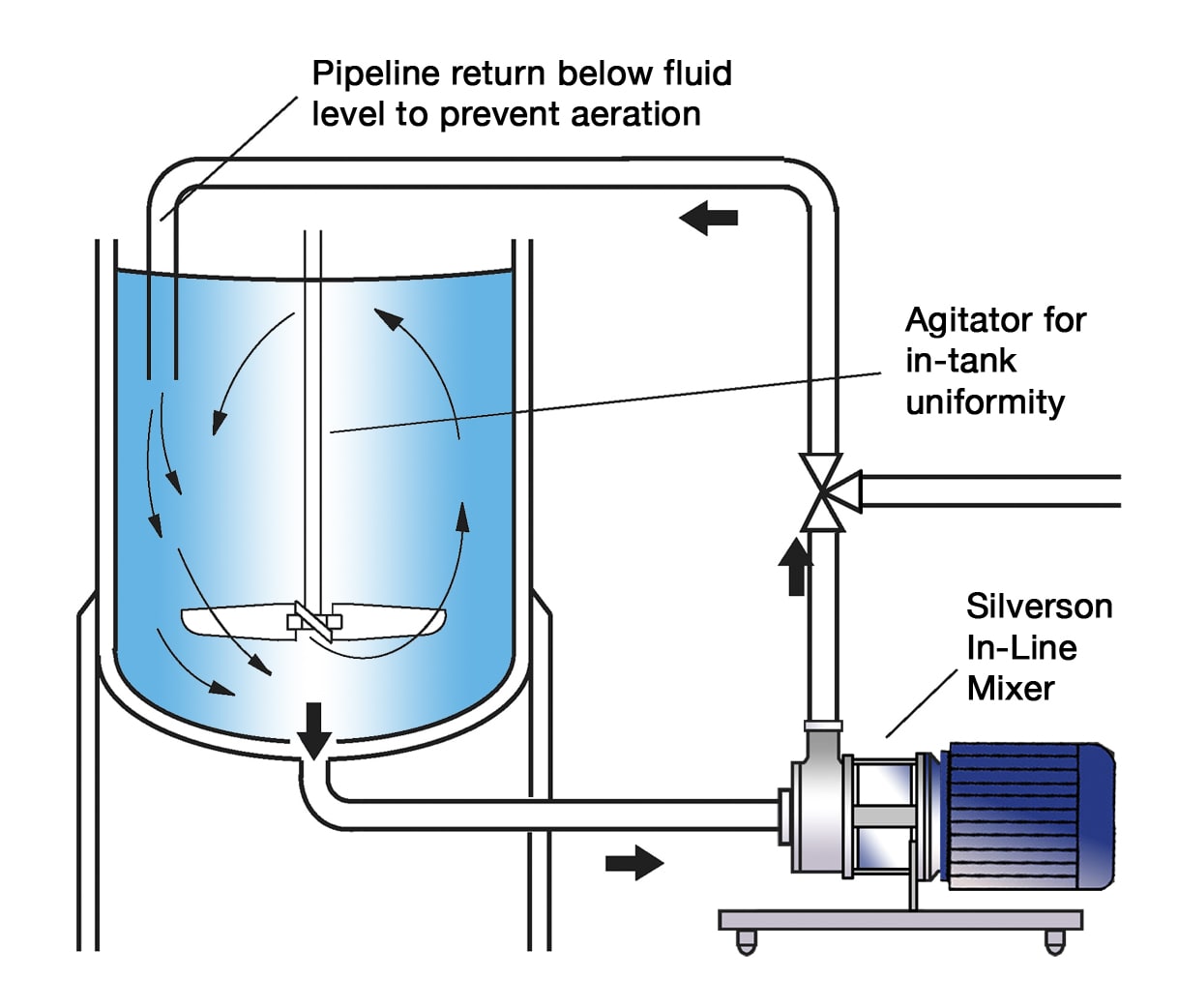

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to an existing plant

- Self-pumping

- Can be used to discharge vessel

- Ultra Sanitary models available

- High viscosity models available

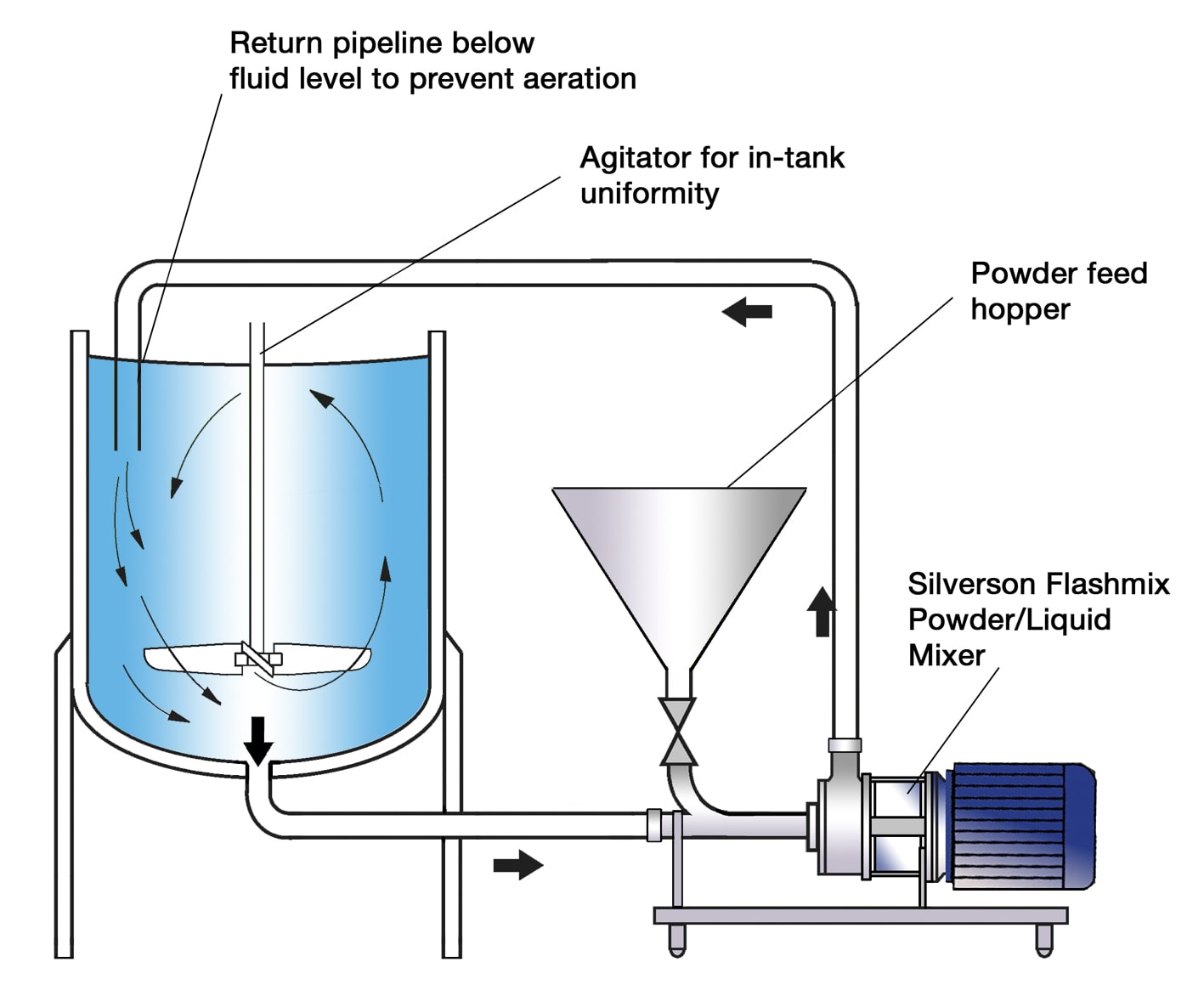

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required

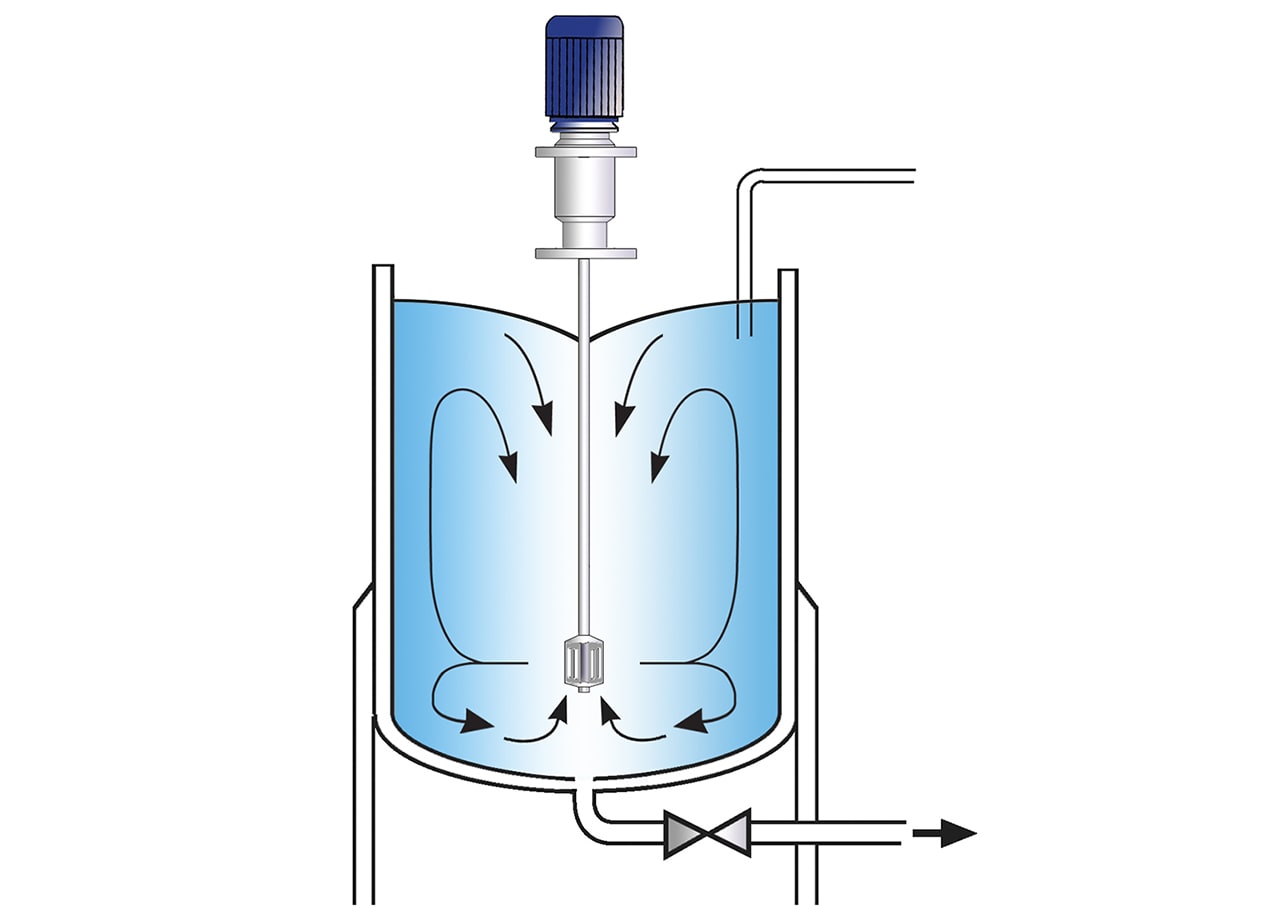

Silverson Ultramix

- Ultra Sanitary CIP design

- Excellent in-tank movement

- Capable of rapidly incorporating large volumes of powders

- Ideal for higher viscosity mixes

- Low maintenance