Ultramix Mixers

Ultramix Mixers

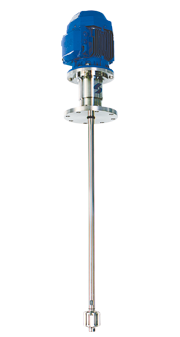

The Silverson Ultramix is a versatile industrial mixer designed to excel in applications that push the limits of conventional agitators and stirrers, without the intense high shear of a rotor/stator mixer. Here’s how the Ultramix tackles your toughest mixing tasks:

Effortless Powder Incorporation

- Effective for Challenging Powders: The Ultramix excels at incorporating difficult powders that tend to float or “raft,” including light-density powders that traditional agitators struggle to overcome due to buoyancy. Its vigorous action also effectively handles fine and cohesive powders, preventing clumps and agglomerates from forming to ensure even distribution throughout your mix.

Narrow Profile, Robust Mixing Performance

- Small Diameter Mixing Head: The narrow profile of the Ultramix is particularly well-suited for use in containers with small openings, such as IBCs (tote bins).

- Durable, Low-Maintenance Design: The simple yet robust design of the single-piece mixing head means there are no wearing parts or bushings, making it a more durable, low-maintenance solution compared to folding impeller mixers which utilize hinges, pivot points or other folding mechanisms that are more prone to wear and failure over time.

Vigorous In-Tank Movement

- The Ultramix creates a powerful axial flow pattern throughout the vessel, ensuring all materials are constantly engaged in the mixing process. Agitators and impellers might not achieve the same level of movement, especially in high viscosity mixes, leaving you with pockets of unmixed material.

Additional Benefits:

- Ultra-Sanitary Design: Single-shaft, single-piece mixing head simplifies cleaning and sanitization, meeting 3A TPV (Third Party Verification), USDA, and cGMP requirements.

- Designed for Clean-in-Place (CIP), Sterilize-in-Place (SIP) Optional: Ensures a hygienic mixing environment for pharmaceutical and food applications, minimizing downtime and simplifying maintenance.

- Versatile Performance: Suitable for a wide range of applications, from aggressive chemical mixing to the most demanding sanitary needs.

How It Works

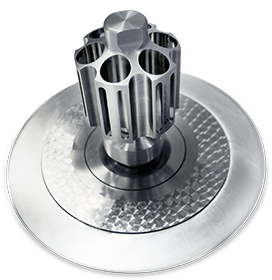

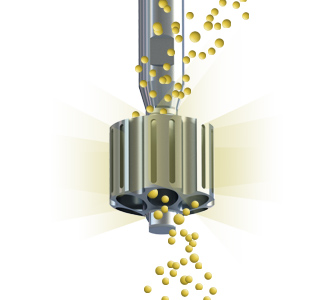

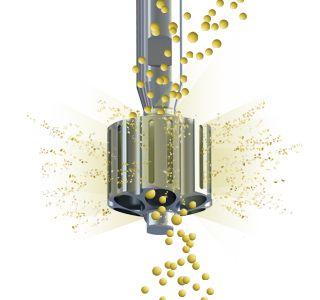

As the mixer rotates at high speed, the grooves on the outside of the dynamic mixing head project the surrounding product outwards with great force, creating an area of low pressure around the trailing edge of each groove.

This draws product from within the mixing head, through the radial slots to the outside, subjecting the material to a shearing action. The grooves in the head drive the product outwards into the body of the mix at high velocity.

As material is drawn out of the slots, fresh material is sucked in through the holes in the top and bottom of the mixing head; this material is then drawn out through the slots and projected back into the mix. The pumping effect of the grooves and the shear action of the radial slots ensures rapid mixing, and develops a vigorous axial flow pattern throughout the vessel.

-

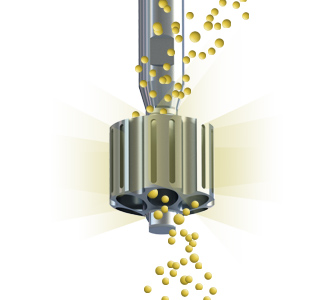

Stage 1

Stage 1

As the mixer rotates at high speed, the grooves on the outside of the dynamic mixing head project the surrounding product outwards with great force, creating an area of low pressure around the trailing edge of each groove.

-

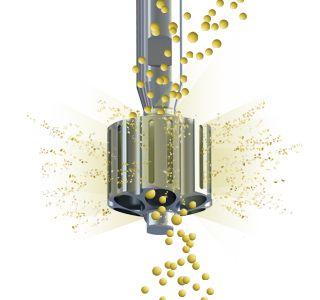

Stage 2

Stage 2

This draws product from within the mixing head, through the radial slots to the outside, subjecting the material to a shearing action. The grooves in the head drive the product outwards into the body of the mix at high velocity.

-

Stage 3

Stage 3

As material is drawn out of the slots, fresh material is sucked in through the holes in the top and bottom of the mixing head; this material is then drawn out through the slots and projected back into the mix. The pumping effect of the grooves and the shear action of the radial slots ensures rapid mixing, and develops a vigorous axial flow pattern throughout the vessel.

Videos

Ultramix – In-Tank Mixer

Ultramix – How It Works

Mixer Options

Technical Information

- Capacity

- 5 - 2000 gallons.

- Materials of Construction

- All wetted parts in 316L stainless steel. Special material on request.

- Motor Specification

- TEFC, washdown duty and explosion proof motors are available as standard.

- Mounting

- Stainless steel flange fitting is available as standard.

- Sealing

- V-ring shaft seal as standard.

- Cleaning

- Clean-In-Place (CIP) design. Simple, easy-to-clean construction.

| Model | HP | RPM | A | B | C | Flange | D | E | F |

|---|---|---|---|---|---|---|---|---|---|

| U1 | 1 | 3600 | 1 ⅞ | 22 | 19 | 3" | 7 ½ | 6 | 4 x ¾ |

| U2 | 3 | 3600 | 2 ¼ | 26 | 22 | 4" | 9 | 7 ½ | 8 x ¾ |

| U4 | 5 | 3600 | 2 ¾ | 41 | 24 | 4" | 9 | 7 ½ | 8 x ¾ |

| U6 | 7.5 | 3600 | 3 ¼ | 55 | 33 | 6" | 11 | 9 ½ | 8 x ⅞ |

| U7 | 10 | 3600 | 3 ½ | 55 | 33 | 6" | 11 | 9 ½ | 8 x ⅞ |

| U9 | 10 | 1800 | 4 ½ | 72 | 33 | 6" | 11 | 9 ½ | 8 x ⅞ |

| U10 | 25 | 3600 | 4 ½ | 72 | 42 | 8" | 13 ½ | 11 ¾ | 8 x ⅞ |

| U11 | 20 | 1800 | 5 | 72 | 41 | 8" | 13 ½ | 11 ¾ | 8 x ⅞ |

| U15 | 25 | 1800 | 5 ⅞ | 72 | 45 | 10" | 13 ½ | 11 ¾ | 8 x ⅞ |

The dimensions shown are approximate only and certified diagrams should be used for installation purposes.

Silverson reserves the right to change dimensions and specifications without notice.