Manufacture of Sunscreen Lotion and SPF Cream

The formulation of sunscreen lotion is a complex science. Due to increased demand for higher sun protection factors (SPF), and restrictions on the use of some UV filters in cosmetics, manufacturing technique plays an important part in maximizing the performance of permitted substances.

Sun protection products can be either an oil-in-water or water-in-oil emulsion. These consist of emollients and lubricants, emulsifying and thickening agents, perfume, color, preservatives and UV filter and absorbers such as titanium dioxide or zinc oxide. Effective UV protection is dependent on completeness of dispersion and on particle size of the UV filters and absorbers.

The Process

A typical manufacturing process would be as follows:

- Flake/powder ingredients, such as cetyl alcohol and stearic acid, sometimes dry blended in advance, are dispersed into the oil phase.

- The water phase is prepared separately, containing emulsifiers and stabilizers such as Veegum® or Carbopol®.

- The two phases are then mixed to form an emulsion. This is aided by heating to between 110 and 185℉ (45 - 80℃) depending on ingredients.

- UV filters and absorbers are supplied as dry powder or predispersed in either oil or aqueous bases. Depending on raw material type and formulation requirements these "micronized oxides" are dispersed into the appropriate phase or added to the product once the emulsion has been formed.

- Mixing is continued until the end product is homogeneous.

The Problem

A number of problems can be encountered when mixing sun protection products using conventional agitators:

- Hydration of thickening and suspending agents is one of the most difficult of all mixing operations. In this application, incomplete hydration or formation of agglomerates can have a detrimental effect on SPF.

- When adding powdered ingredients, partially hydrated material can build up on the vessel wall.

- The emulsion has to be totally stable with the minimum addition of emulsifiers and stabilizers as certain additives can reduce SPF. Conventional mixing equipment cannot easily achieve this even when the oil and water phases have been heated.

- UV absorbers are supplied in micronized form or predispersed in oil or water bases. Conventional mixers and agitators are not capable of breaking these down to their smallest constituent parts.

- Long process times and additional equipment may be required to achieve a homogeneous product.

The Solution

Intermediate stages of production can be eliminated, product quality improved and processing times dramatically reduced by using a Silverson High Shear Mixer:

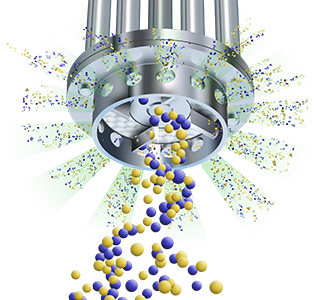

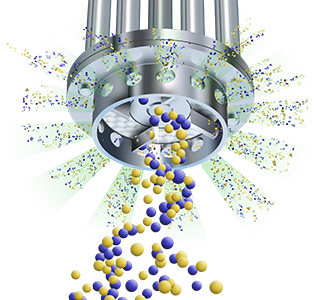

Stage 1

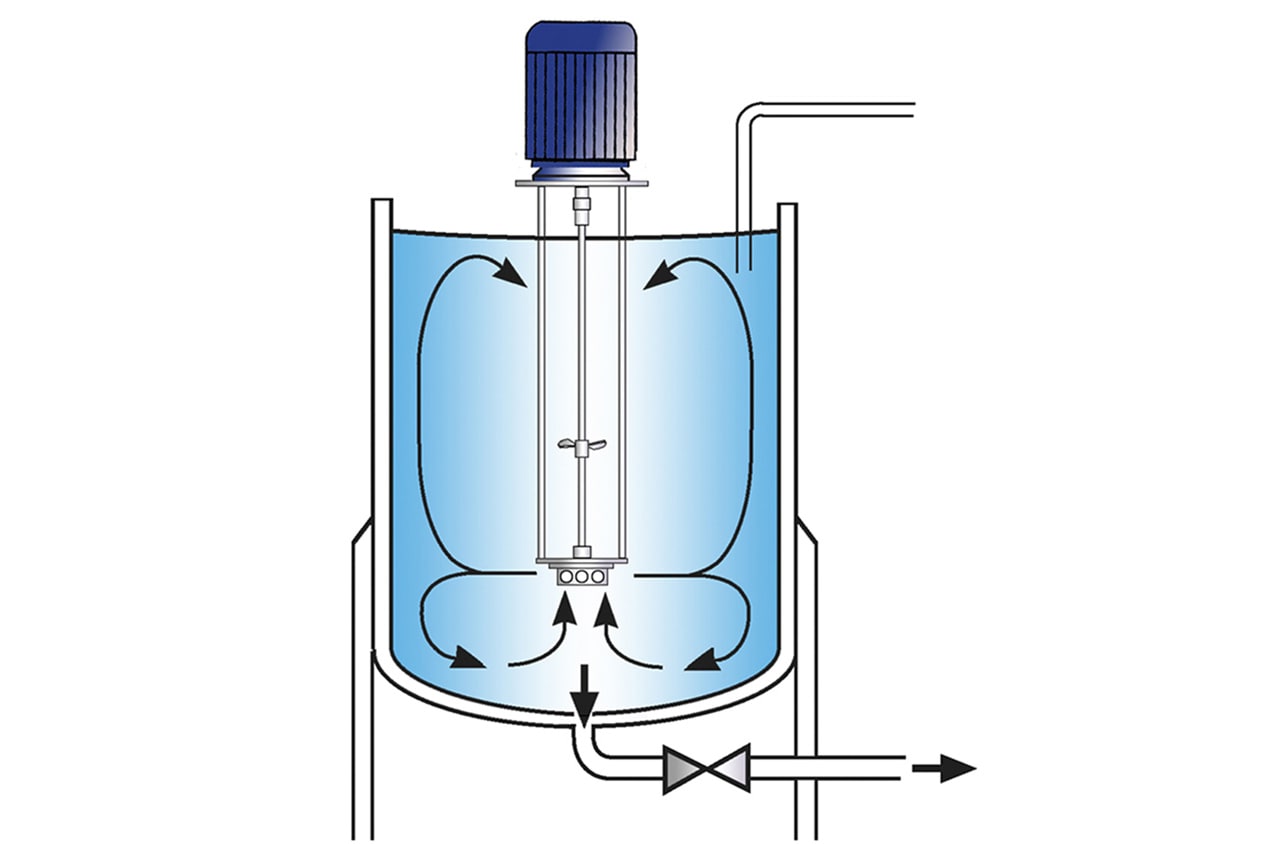

The vessel is charged with the “continuous” phase. The Silverson mixer is started, and the solid/powdered ingredients are then added. The powerful suction created by the high speed rotation of the rotor blades draws both liquid and solid ingredients into the workhead where they are rapidly mixed.

Stage 2

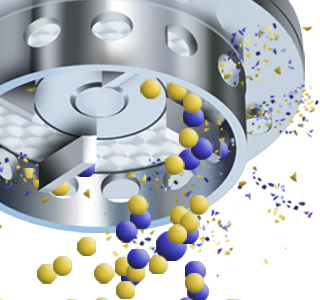

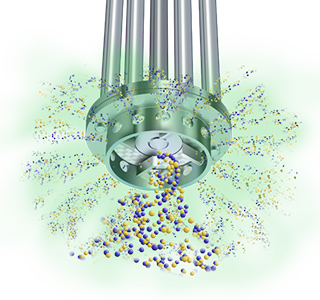

The solids are broken down in the precision machined clearance between the rotor and the stator wall. The ingredients are fully dispersed into the liquid before being forced out through the stator and circulated into the body of the mix. At the same time fresh material is drawn into the workhead.

Stage 3

The intake and expulsion of materials sets up a circulatory pattern of mixing in the process vessel. As the “dispersed” phase is added, the high shear mixing action of the rotor/stator workhead dramatically reduces globule size to ensure a uniform and stable emulsion is rapidly formed.

Stage 4

Micronized oxides can be added at this stage. The high shear action of the Silverson workhead rapidly breaks down agglomerates and reduces the material to its smallest constituent parts. The micronized oxides are rapidly dispersed throughout the emulsion in a matter of minutes.

-

Stage 1

Stage 1

The vessel is charged with the “continuous” phase. The Silverson mixer is started, and the solid/powdered ingredients are then added. The powerful suction created by the high speed rotation of the rotor blades draws both liquid and solid ingredients into the workhead where they are rapidly mixed.

-

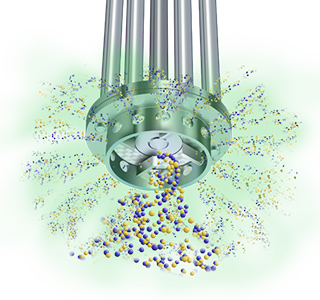

Stage 2

Stage 2

The solids are broken down in the precision machined clearance between the rotor and the stator wall. The ingredients are fully dispersed into the liquid before being forced out through the stator and circulated into the body of the mix. At the same time fresh material is drawn into the workhead.

-

Stage 3

Stage 3

The intake and expulsion of materials sets up a circulatory pattern of mixing in the process vessel. As the “dispersed” phase is added, the high shear mixing action of the rotor/stator workhead dramatically reduces globule size to ensure a uniform and stable emulsion is rapidly formed.

-

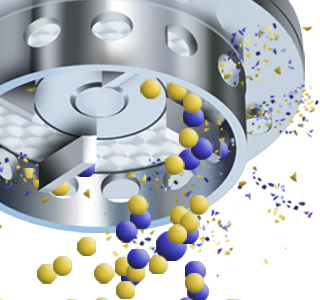

Stage 4

Stage 4

Micronized oxides can be added at this stage. The high shear action of the Silverson workhead rapidly breaks down agglomerates and reduces the material to its smallest constituent parts. The micronized oxides are rapidly dispersed throughout the emulsion in a matter of minutes.

The Advantages

- Improved dispersion of micronized oxides obtained using a Silverson high shear mixer results in better SPF.

- Consistent product quality and repeatability.

- Rapid mixing time.

- Maxmized yield of other raw materials. Thickening agents are fully hydrated and other materials are fully dispersed.

- Agglomerate-free mix.

- Stable emulsion.

The batch size, formulation, type of ingredients and the viscosity of the end product dictate which Silverson machine is best suited to individual processing requirements:

High Shear Batch Mixers

- Suitable for batch sizes up to 400 US gallons

- Can be used on mobile floor stands

- Sealed units available for pressure/vacuum operation

- Small units available for R&D and pilot production

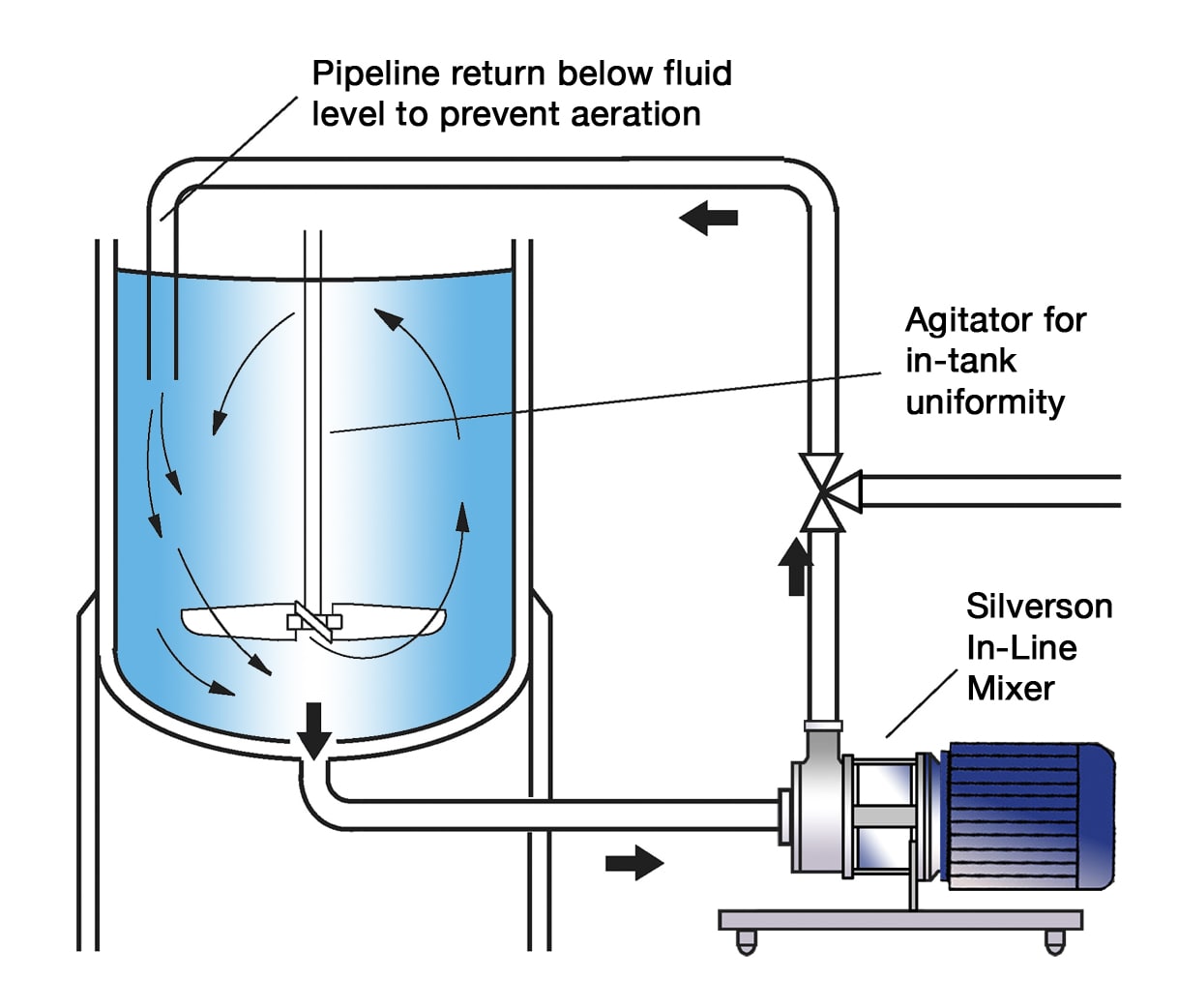

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to existing process

- Self-pumping

- Can be used to discharge the vessel

- Multistage units available

- Ultra Sanitary units available

- High viscosity models available

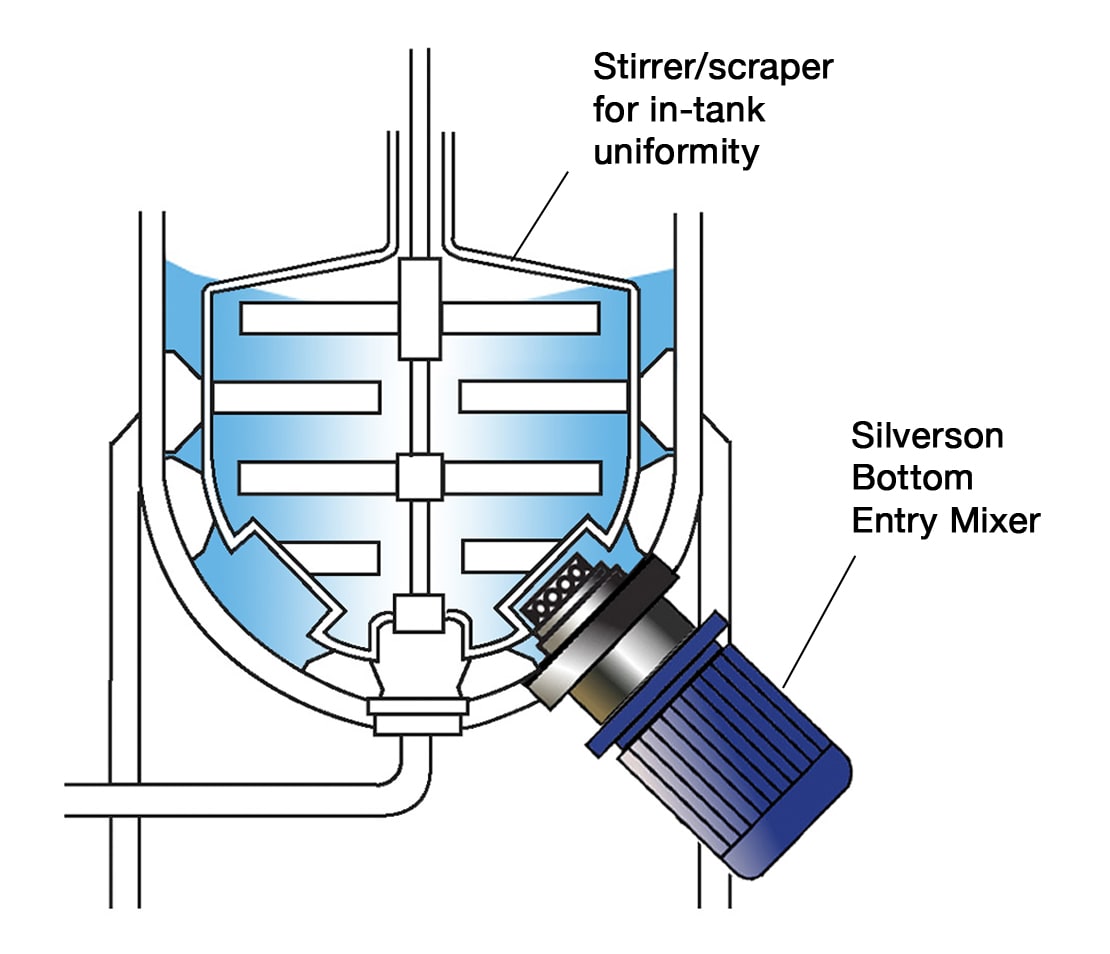

High Shear Bottom Entry Mixers

- Generally used in conjunction with an anchor stirrer/scraper

- Suitable for use on high viscosity products - gels, deodorant sticks or those that increase in viscosity or solidify on cooling