Dispersion of Pectin for Jelly and Preserves

Pectin is a polysaccharide obtained from a variety of fruits. It is used as a thickening and gelling agent in a wide range of foods, including jelly, jam, marmalade and other preserves.

The Process

In a typical manufacturing process, pectin solution is prepared separately and added to the jelly once dispersion and hydration has been completed. A typical dispersion process would be as follows:

- The processing vessel is charged with water which has been heated to 140-175ºF (60 - 80ºC).

- The agitator is started.

- The pectin is sometimes premixed dry with another powdered ingredient, such as sugar typically 1 part pectin to 3 parts sugar. This reduces the formation of agglomerates by separating the grains and also “weights” the pectin to prevent it floating on the water.

- Alternatively the pectin may be predispersed into liquids such as syrup.

- The pectin is gradually added into the vortex created by the agitator.

- Mixing is continued after the pectin has been dispersed to allow hydration to be completed.

- Product can be held at 140ºF for up to 4 hours, although at higher temperatures degradation can occur after 1 hour and product should be used immediately.

- The solution is sometimes filtered before addition to the jelly.

Case Study: Pectin Use Slashed by 20% with High Shear Mixing

The Problem

Dispersion of gums and thickeners such as pectin using conventional agitators can give rise to several problems:

- Agglomerates can easily form. Pectin particles remain undissolved inside the agglomerates. Conventional mixers and agitators do not produce sufficient shear to properly disperse the particles or rapidly break down agglomerates.

- Potential full yield is difficult to obtain using traditional methods.

- Powder addition must be carried out with great care to reduce agglomerates.

- Dry premixing of powdered ingredients increases labor costs and process time.

- Once viscosity increase has started, agitation of the solution and therefore powder dispersion becomes increasingly difficult.

- Long mixing times are required to complete dispersion/hydration.

- Filtration of poorly dispersed solutions considerably adds to process times.

- Partially hydrated pectin removed during filtration is wasted, increasing costs and reducing product quality.

- Undissolved pectin can gradually hydrate during storage or subsequent processing, leading to undesired changes in product viscosity.

The Solution

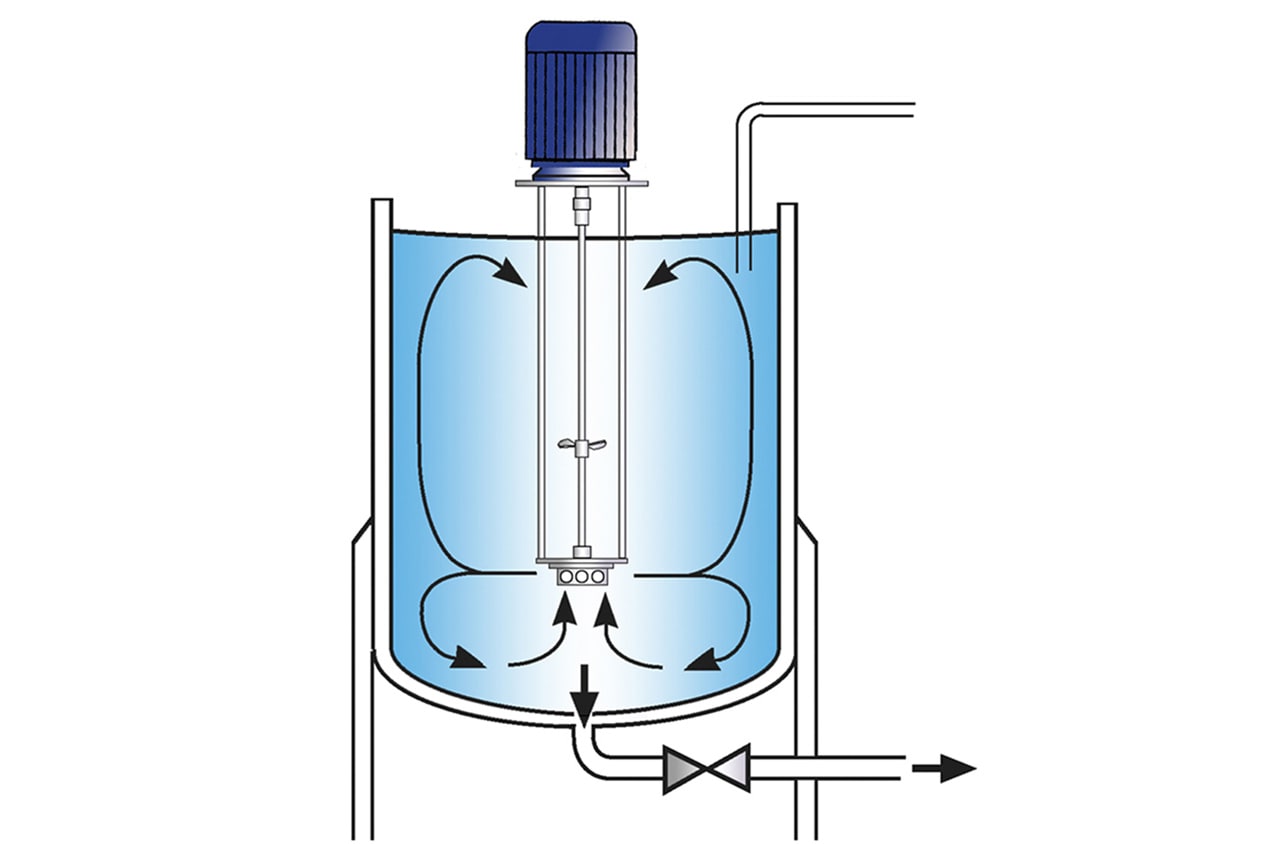

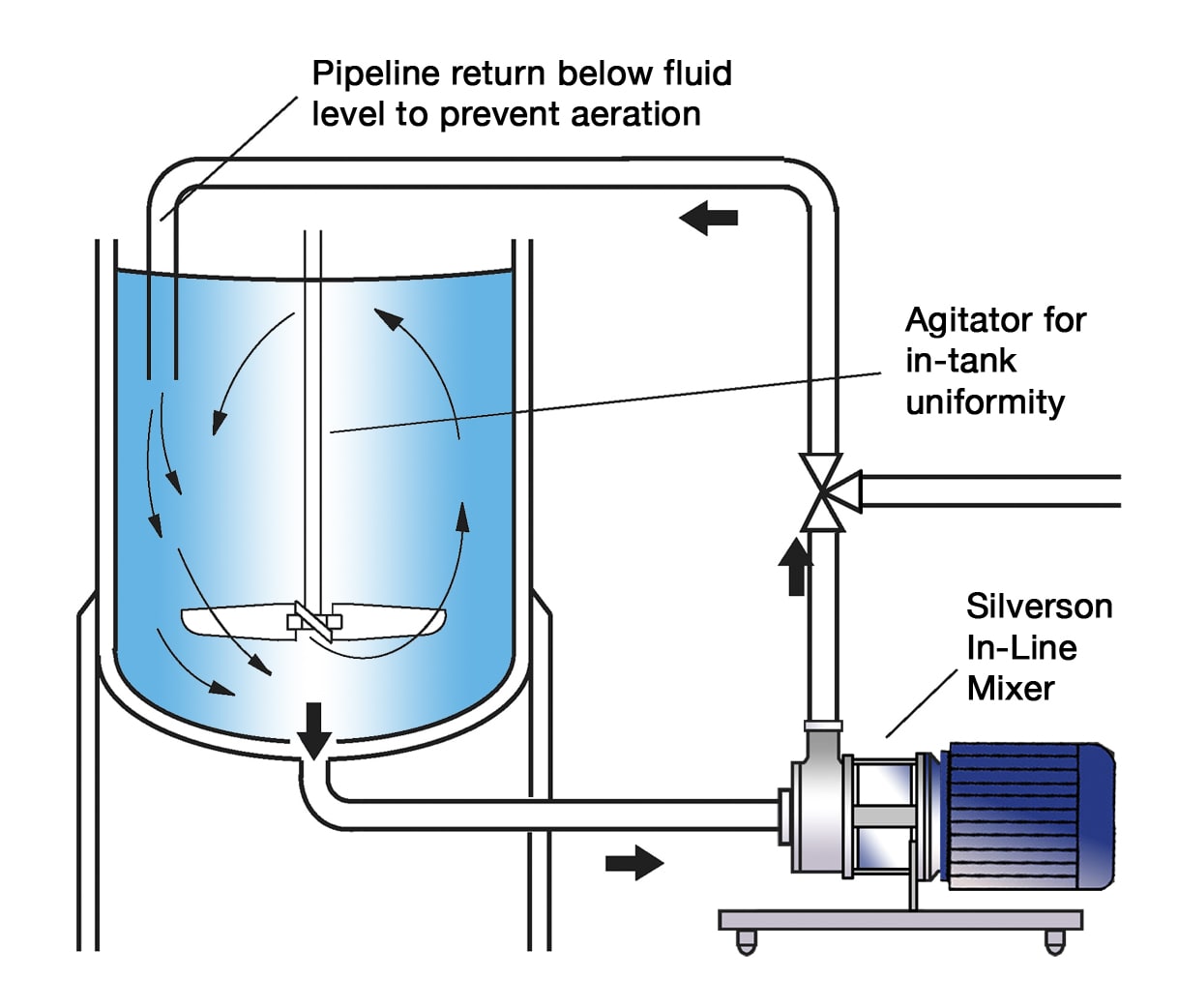

A Silverson High Shear mixer can dramatically reduce processing times, improve product quality and eliminate the need to premix powders. This can be achieved using a Batch mixer immersed in the vessel, or an In-Line mixer can be added to an existing process as illustrated below. Operation is as follows:

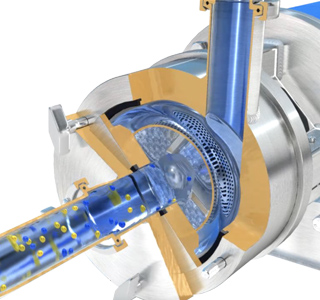

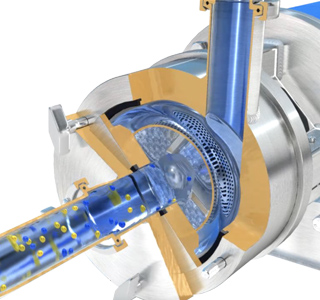

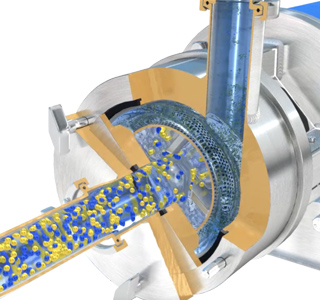

Stage 1

The pectin is added to the water and dispersed by the in-tank agitator. The high speed rotation of the In-Line mixer's rotor blades creates a powerful suction which draws the water and pectin particles from the vessel into the workhead.

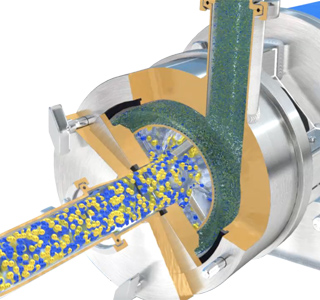

Stage 2

The materials are subjected to intense shear in the confined area of the workhead. Agglomerates are broken down in the gap between the rotor blades and stator wall, exposing an increasing area of pectin to the surrounding liquid.

Stage 3

The product is forced out of the stator and returned to the vessel by the self-pumping In-Line mixer. Fresh material is simultaneously drawn into the workhead. In a short mixing cycle all the material passes through the workhead, accelerating the hydration process.

-

Stage 1

Stage 1

The pectin is added to the water and dispersed by the in-tank agitator. The high speed rotation of the In-Line mixer's rotor blades creates a powerful suction which draws the water and pectin particles from the vessel into the workhead.

-

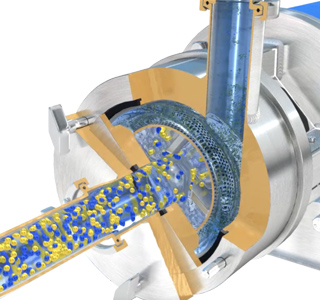

Stage 2

Stage 2

The materials are subjected to intense shear in the confined area of the workhead. Agglomerates are broken down in the gap between the rotor blades and stator wall, exposing an increasing area of pectin to the surrounding liquid.

-

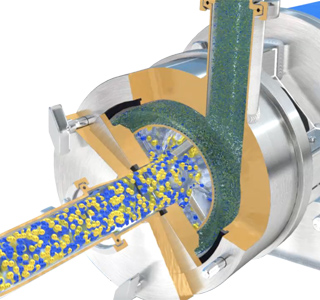

Stage 3

Stage 3

The product is forced out of the stator and returned to the vessel by the self-pumping In-Line mixer. Fresh material is simultaneously drawn into the workhead. In a short mixing cycle all the material passes through the workhead, accelerating the hydration process.

The Advantages

- Solution can be achieved at ambient temperature, depending on the concentration and viscosity of the end product.

- Agglomerate-free mix.

- Dry premixing is not necessary.

- Rapid powder absorption rate minimizes operator error.

- Yield of the pectin is maximized, obtaining full thickening/gelling effect.

- Filtration stage can be eliminated, or where necessary, filtration times are greatly reduced.

- Stable viscosity of end product.

- Consistent product quality and repeatability.

- Rapid mixing times.

The batch size, formulation, type of ingredients and the viscosity of the end product dictates which machine from the Silverson product line is suited to individual processing requirements:

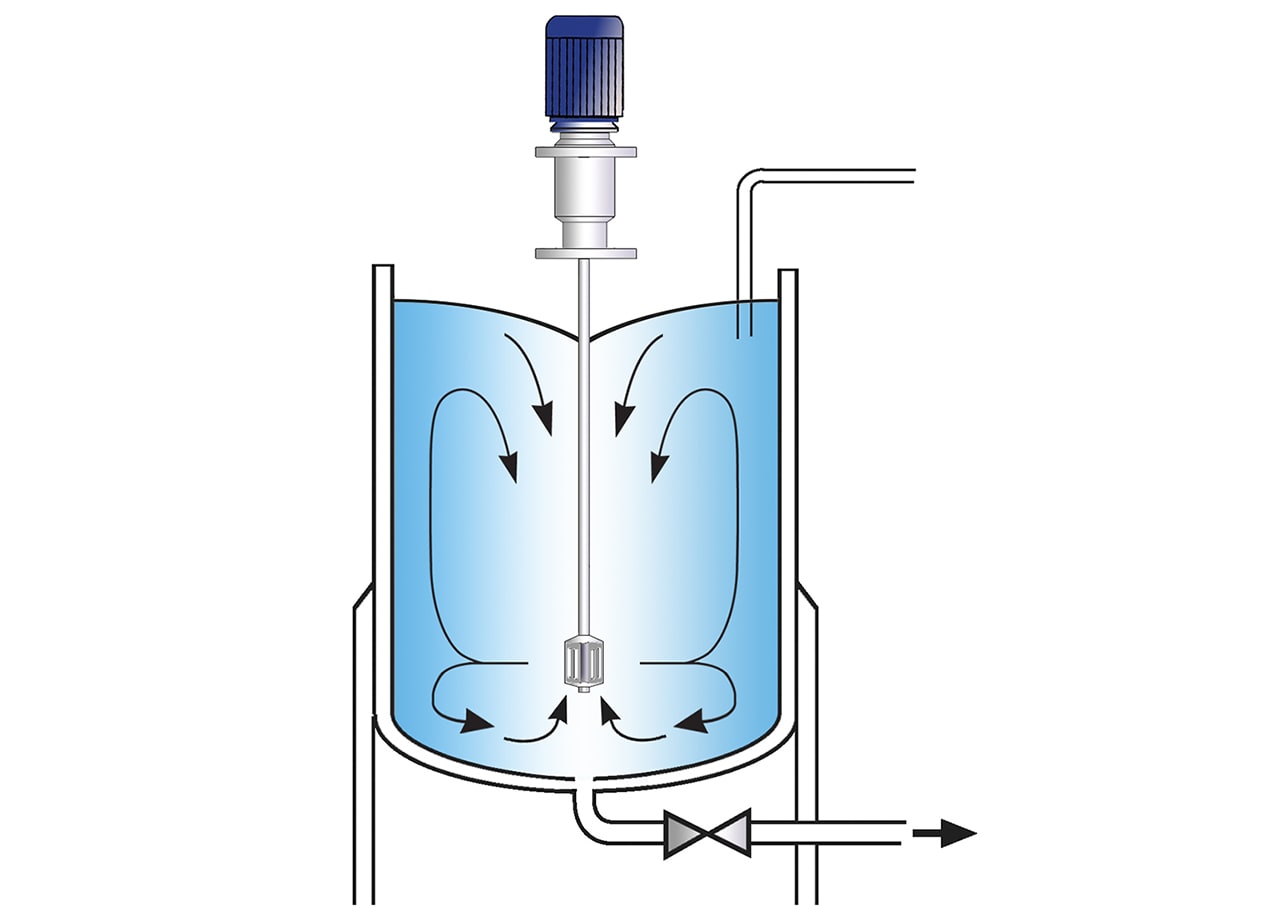

High Shear Batch Mixers

- Suitable for batches up to 400 US gallons

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

Silverson Ultramix

- Excellent in-tank movement

- Capable of rapidly incorporating large volumes of powders

- Ultra Sanitary CIP design

- Ideal for higher viscosity mixes

- Low maintenance

High Shear In-Line Mixers

- Easily retrofitted to existing plant

- Ideal for larger batches

- Aeration free

- Self-pumping

- HV In-Line mixers available for higher viscosity mixes

- Can be used to discharge vessel

- Designed to be Cleaned-In-Place

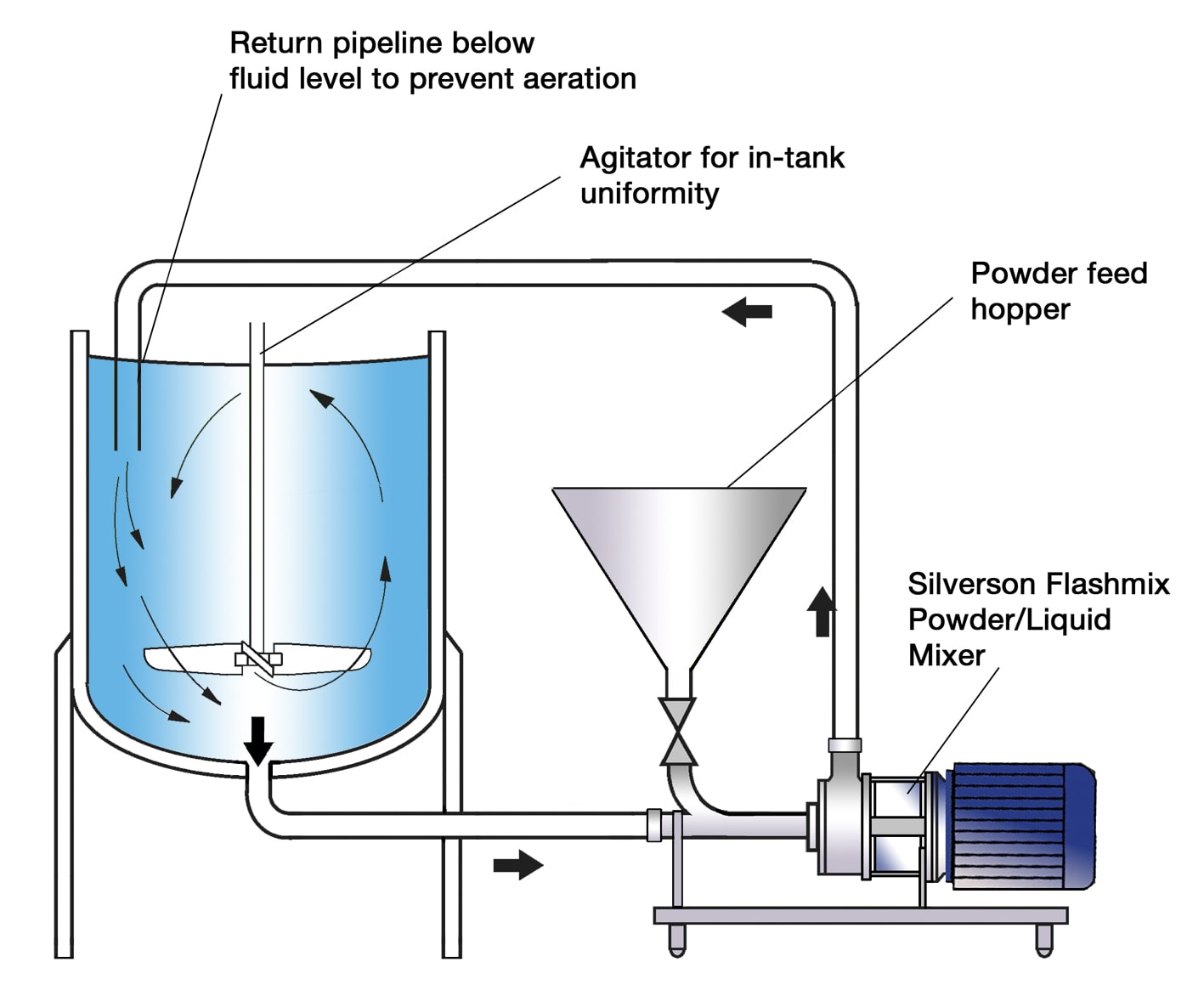

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required