Pilot Scale Batch Mixers

Pilot Scale Batch Mixers

This series of mixers are designed for small scale production in pilot plants, research institutions, hospital pharmacies, etc. Light and easily operated, AX series models have a capacity of up to 50 liters.

The Silverson multifunctional AX5 laboratory mixer features a range of instrumentation invaluable where process validation and reproducibility is required and provides an accurate and easy means of forecasting the performance of larger Silverson machines under full-scale working conditions.

The AX5 is suitable for the widest range of applications - mixing, emulsifying homogenizing, disintegrating, dissolving - with an efficiency and flexibility unmatched by other machines.

Features:

- Powerful 1HP (0.75 kW) motor

- Touch pad controls

- Electric rise & fall bench stand

- Variable speed. Nominal maximum speed 6000 rpm

- Compatible with the DataLogger system

- Nominal capacity of up to 50 litres

How It Works

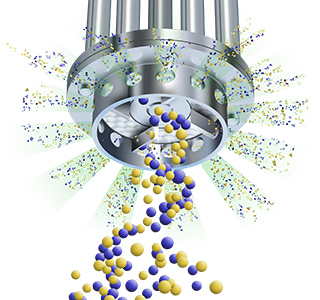

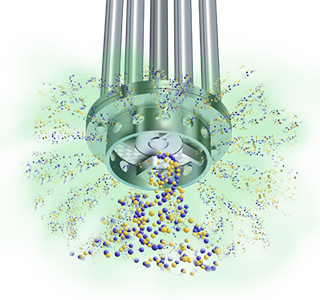

The advantages of Silverson’s high shear rotor/stator batch mixer over simple conventional stirrers or agitators stem from the multistage mixing/shearing action as materials are drawn through the specially designed Silverson workhead - the heart of every machine.

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead.

Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix.

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid’s surface.

-

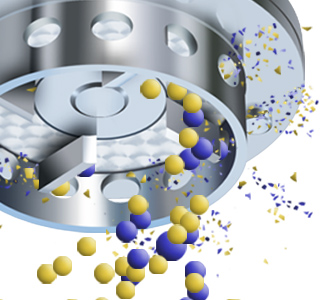

Stage 1

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead.

-

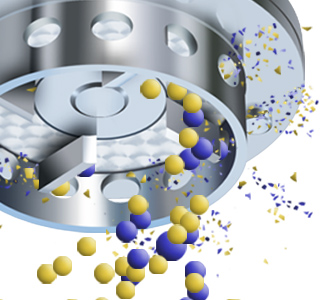

Stage 2

Stage 2

Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

-

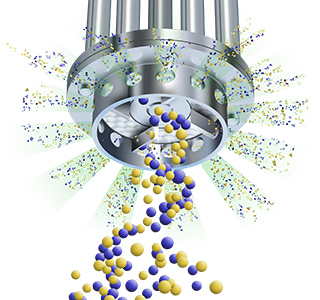

Stage 3

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix.

-

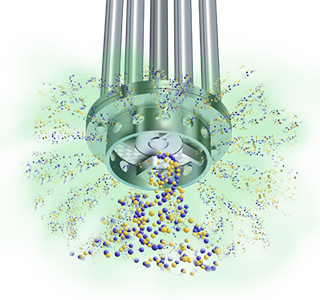

Stage 4

Stage 4

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid’s surface.

Videos

AX Range – Pilot Scale Batch Mixers

Interchangeable Workheads

Mixer Options

Workheads

A comprehensive range of workheads and screens is available for all Silverson high shear mixers. These easily interchangeable workheads offer great versatility by allowing any machine to be adapted to perform a wide range of mixing operations including emulsifying, homogenizing, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating. Changing from one head or screen to another is quick and simple.

Technical Information

AX5 Series

Download Printable Version (PDF)- Capacity

- AX Series models have a capacity of up to 50 liters.

- Motor

- 1hp (750W) 110 volt, single phase (220 volt optional), 60 Hz. Nominal maximum speed 6000 rpm.

- Speed Control

- Infinitely variable electronic speed control with integral on/off switch. The unit features a “speedlock” function designed to maintain the required speed as product viscosity rises or falls during operation.

- Stand

- The mixing unit may be effortlessly raised and lowered using the push-button control on the motor unit.

- Construction

- Finished in a tough, easy to clean non-chip white nylon coating. All wetted parts in 316L stainless steel except the bush which may be bronze alloy or PTFE.

- Assemblies

- Compatible with the Duplex and Ultramix mixing assemblies.

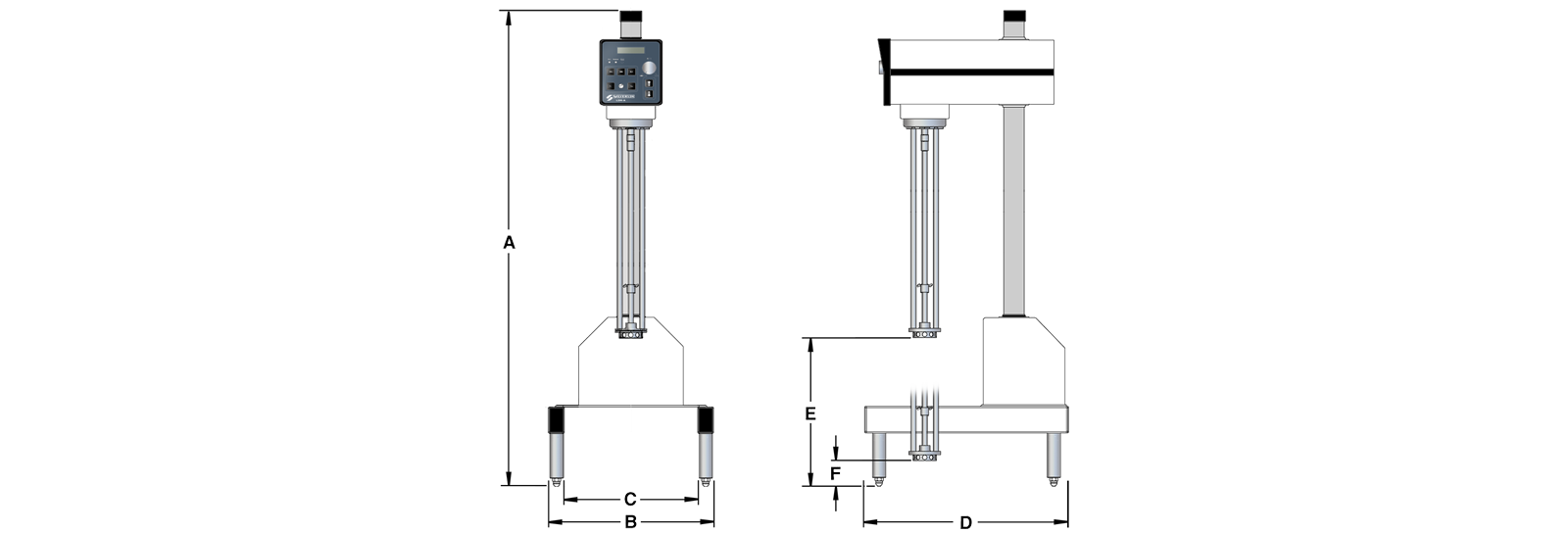

| Model | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| AX5 | 43 3/16 | 20 11/16 | 17 11/16 | 19 5/8 | 14 1/16 | 2 3/8 |

All dimensions shown are in inches. The dimensions shown are approximate only and certified diagrams should be used for installation purposes. Silverson reserves the right to change dimensions and specifications without notice.